- Brew Great Beer

- Posts

- Hop Oils vs. Pellets: Tiny Droplets, Big Aroma

Hop Oils vs. Pellets: Tiny Droplets, Big Aroma

Compare hop pellets to modern concentrated hop oils for bitterness and aroma. Learn pros, cons, yield savings, and decide if tiny droplets can replace leafy tradition.

Good morning. Today is the last article that I will be writing for the Brew Great Beer newsletter due to a change in management - I have to say, it has been my honor and privilege to write to you every Sunday the last 91 weeks. I hope you all continue to brew great beer for many years to come - I know I will. Cheers and happy brewing!

-Brandon Copeland

Hop Oils vs. Pellets: Tiny Droplets, Big Aroma

Homebrewers chasing maximum hop expression face an increasingly popular choice: stick with trusty pellets or pivot to concentrated hop oils/extracts. Hop oils deliver the same - or bigger - aroma payload with a fraction of the vegetal matter, boosting yield and reducing “green” flavors, while pellets remain the all-around workhorse for bitterness, mouthfeel and tradition. Below, we sort through how each format is produced, where they excel (or fall short), and how brewers are pairing the two for layered hop character.

Hop Pellets 101

Pellets are kiln-dried hop cones milled and compressed, preserving most alpha-acids and volatile oils yet introducing up to 600 g of vegetal matter per barrel in heavily hopped beers - material that soaks up wort and beer.

Pros: familiar, easy to dose, deliver bitterness and “raw hop” polyphenols beloved in West-Coast styles.

Cons: trub losses, tank blocking, and grassy flavors when used in very high dry-hop rates.

What Are Hop Oils & Extracts?

Modern extracts are produced by CO₂ or ethanol washing of pellets, capturing alpha-acids and delicate terpenes in a flowable resin—or in “fully dispersible” cold-side liquids such as FLEX® and SPECTRUM™. These products contain zero green matter, so nothing soaks up finished beer. Brewers report yield bumps of 3–5 % on hazy IPAs when swapping part of the dry-hop for oils.

Flavor & Aroma Head-to-Head

Attribute | Pellets | Hop Oils / Spectrum-type |

|---|---|---|

Vegetal character | Noticeable above ~4 lb/bbl | Minimal, cleaner bitterness |

Late-ferment aroma | Robust but volatile | Intense, survives cold side |

IBU accuracy | Varies batch to batch | Highly consistent alpha content |

Beer losses | 0.5–1 gal per 5 gal heavily hopped | Negligible - no leaf mass |

Early trials at Blind Tiger Brewery showed hop extract “reduced plant-matter flavor” while still letting late-kettle additions shine.

Best-Practice Pairings

Bittering – a single 5 mL CO₂ extract shot (≈35 IBU) replaces a 60-min pellet addition while eliminating kettle trub.

Whirlpool – half-pellet, half-oil provides familiar hop “bite” plus saturated fruit aroma, according to brewers on r/TheBrewery.

Cold-Side – SPECTRUM™ or similar flowables are dosed directly into brite tanks, dispersing in minutes without O₂ pickup.

Downsides & Caveats

Sticker shock – milliliter for milliliter, oils cost more up front, though savings appear in higher finished-beer yield.

One-dimensional risk – some sensory panels find oil-only dry hops lack hop “texture” compared to pellets.

Learning curve – overdosing can push solvent-like intensity; most suppliers recommend starting at 20–30 % of your usual pellet rate.

When to Reach for Each Format

Goal | Choose Pellets | Choose/Oil-Pellet Blend |

|---|---|---|

Old-school West-Coast bite | ✔️ | |

Hazy IPA with less hop-burn | ✔️ (50 % oil in cold side) | |

Maximizing yield in a small fermenter | ✔️ | |

Budget bittering addition | ✔️ 60-min pellet | ✔️ CO₂ extract shot (if counting tank losses) |

Homebrew Equipment of the Week

Ditch the propane and shrink your footprint with BrewZilla’s latest 35 L (9.25 gal) rig. The Gen 4.1 packs a Wi-Fi/Bluetooth RAPT controller so you can pre-heat strike water from your phone and log every temp swing in the cloud. A built-in recirculation pump, redesigned false bottom, and stainless malt pipe lift make step-mashes easier than spreadsheet brewing. The included immersion chiller clips directly to the lid port—ready to whirlpool or chill without extra gear. At 110 V it plugs into a standard outlet, giving apartment brewers pro-grade control in a single, easy-to-clean vessel.

Beer Trivia Question

🍺 Which U.S. brewery first used supercritical CO₂ hop extract in large-scale production during the 1970s, pioneering the commercial adoption of hop oils?

Read to the end to find out if you're right!

Brewgr Recipe of the Week

When you see a recipe that is “V5”, you have to trust that after that much trial and error, it has to at least be decent. This Czech Pilsner lives up to the hype, using primarily pilsner malt and Saaz hops, followed up with Omega Pilsner yeast.

Credit: Musty Ditch

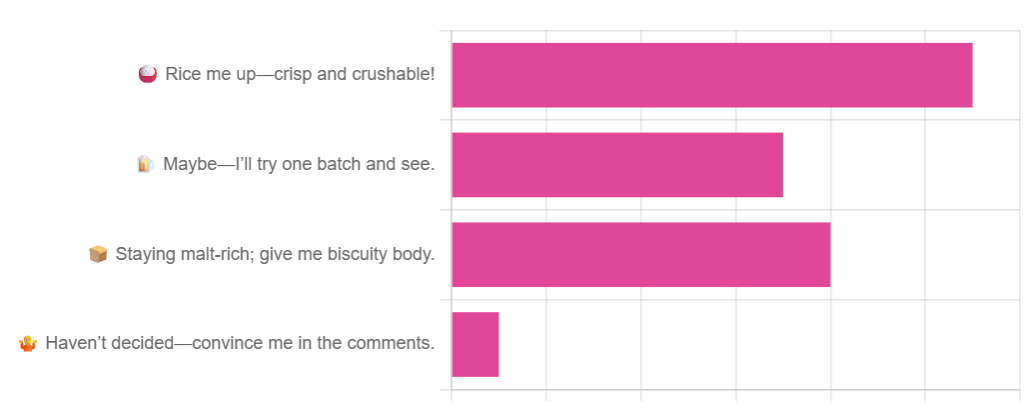

This last newsletter inspired quite a few of you to brew a rice lager, although some of you mentioned in the heat of the summer a lager wouldn’t fit in your set up. That’s what homebrewing is all about - trying new things and seeing how they taste!

And the Answer Is...

🍺 Anheuser-Busch pioneered large-scale use of supercritical CO₂ hop extract in the mid-1970s. The breakthrough trimmed vegetal trub and gave beers like Budweiser more consistent bitterness.

P.S. If you want to make sure you receive this newsletter to your inbox every week, do the following:

Reply “OK” to this email. It helps ensure you receive our news.

Move this email to your “primary” inbox if it’s in promotions or spam.

Add [email protected] to your email contacts (updated from last week)

This newsletter contains affiliate links - we will earn a commission on the sale of particular items with no extra cost to you.

Happy Brewing!

- Brandon, Brew Great Beer Team

Reply